Under the leadership of Mr. Krastev the following materials have been developed and implemented into production:

- Electric insulation varnishes of thermal resistance class F

- Electric insulation varnishes of thermal resistance class F

- A series of non-saturated esterimide varnishes without solvents (compounds) with excellent insulating properties, high cementing capacity and superb chemical resistance against acids, alkalis, freons and other chemical reagents

- Impregnation varnishes

- Vinylester varnishes with excellent chemical resistance

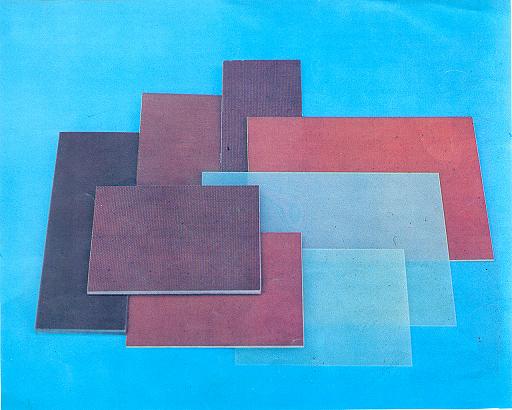

- A series of polyester press-materials (premixes), DIN 16 911, type 803, well-known under the trade name "Esterplast" with excellent electric insulation properties, high mechanical strength and tracking resistance

- A range of profile glass-plastics – glass-roving slot wedges

- Molding compositions for electrical engineering products – polyester, esterimide and epoxy

- Epoxy glues

POLYESTER PRESS-MASSES – PRE-MIXES

They are doughy press-masses, synthesized on the base of non-saturated polyester or polyester-imide resins, alkali-free glass, mineral fillers, hardeners and additives for special application.

The pre-mixes are produced in Bulgaria under the ESTERPLAST trade mark. Their area of application is the production of elements of high voltage devices with special requirements of mechanical strength, thermal resistance and electric insulation performance.

The pre-mixes of the ESTERPLAST series comply with the technical requirements of DIN 16 911, type 803.

They are formed by compressing, blowing and molding under pressure at the following conditions:

- Temperature, C 160-170C

- Pressure: 10/5Pa 100-250 (depending on the complexity of the elements)

- Time of pressing, s/mm: 15-30 (depending on the wall thickness of the elements).

The polyester press-materials possess very high tracking resistance properties.

They are doughy press-masses, synthesized on the base of non-saturated polyester or polyester-imide resins, alkali-free glass, mineral fillers, hardeners and additives for special application.

The pre-mixes are produced in Bulgaria under the ESTERPLAST trade mark. Their area of application is the production of elements of high voltage devices with special requirements of mechanical strength, thermal resistance and electric insulation performance.

The pre-mixes of the ESTERPLAST series comply with the technical requirements of DIN 16 911, type 803.

They are formed by compressing, blowing and molding under pressure at the following conditions:

- Temperature, C 160-170C

- Pressure: 10/5Pa 100-250 (depending on the complexity of the elements)

- Time of pressing, s/mm: 15-30 (depending on the wall thickness of the elements).

The polyester press-materials possess very high tracking resistance properties.

IMPREGNATION VARNISHES WITHOUT SOLVENTS (COMPOUNDS)

They are solutions in monostyrene of modified esterimides, polymerizing (hardening) under treatment with a system of hardeners and accelerators (catalysts). An esterimide varnish without solvents (impregnating compound) under the PE.9.155 trade mark is produced in Bulgaria. Compared with traditional impregnating varnishes, where during the hardening process more than 50% of volatile substances are being released into the surrounding atmosphere, this amount for the compounds does not exceed 5-8%. PE.9.155 varnish possesses high cementing capabilities and thermal resistance as well as excellent electric insulation properties. Application: coils impregnation of electrical devices with thermal resistance class F (155C). Depending the hardening system (hardener and catalyst) chosen, the compounds are hardening at 25+/-5C (cold hardening) or at 120C (hot hardening).

Site News

Suspendisse potenti. Quisque dignissim, ligula at imperdiet mollis, arcu nisl hendrerit metus, ac venenatis

Suspendisse potenti. Quisque dignissim, ligula at imperdiet mollis, arcu nisl hendrerit metus, ac venenatis

Suspendisse potenti. Quisque dignissim, ligula at imperdiet mollis, arcu nisl hendrerit metus, ac venenatis